Based on the direction of movement

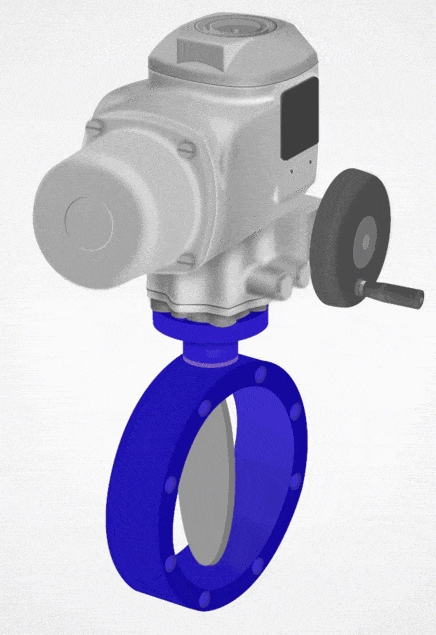

Linear Actuators

Source

Linear Actuators can move a particular component in a linear direction only. The efficiency of a linear actuator can be determined using its speed, torque, durability and energy consumption. Linear Actuators are composed of an AC or DC motor, gearing and a lead or ball screw with a driving nut. The screw rotates along with the motor forcing the nut along the shaft and the connected handle to move linearly. They have a long life and are energy efficient. They are also compact and easy to use.

Applications

- Linear Actuators are used in machines for lifting, dropping, sliding, or tilting materials.

- Linear actuators help robotic machinery interact with its environment by producing movements in clamps. wheels, arms or legs.

- Window automation involves the use of a large linear actuator, also known as a push-rod motor. They can be seen in Shutters, Skylights and Casement windows.

- Machines used in agriculture use linear actuators to control the height and angle of sprayers. They are also used in seed drills and combine harvesters in grain tanks and concave adjustments.

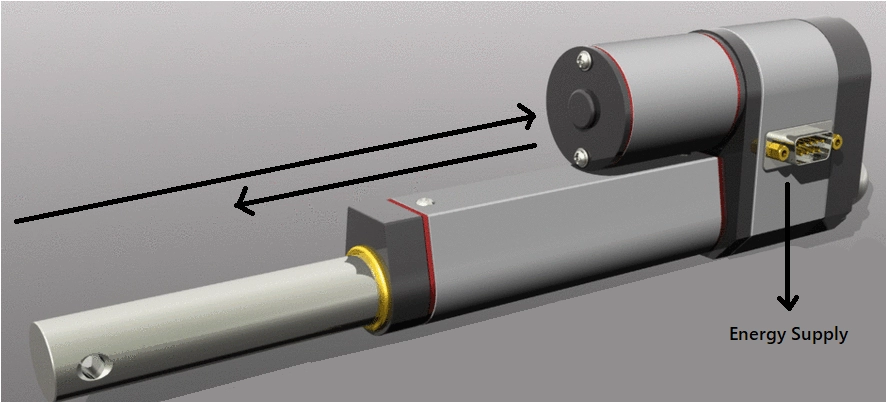

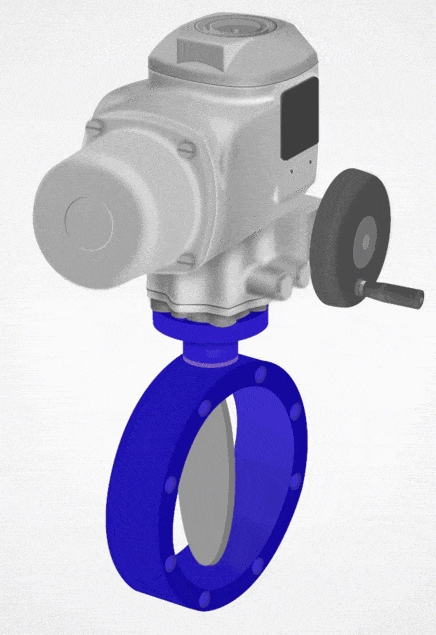

Rotary Actuators

Source

Rotary actuators can move a component in a circular direction. They convert energy into rotary or oscillatory movements. They are primarily used in operating the actions of an automatic or manually controlled valve. They are quite special as they can be connected to other mechanisms to form linear actuators. They are highly efficient and extremely reliable.

Applications

- Rotary actuators are used in the field of aerospace to convert high-speed, low-torque rotary motion, through a gear train, into low-speed and high-torque motion.

- Rotary actuators with multiple helical gears are used in the wheel steering of harvesters, car wipers etc.

- Rotary actuators are used in processing valves in the photochemical industry and other pipelining operations.

Based on the source of energy

Hydraulic Actuators

Hydraulic actuators utilise the power generated from hydraulic motors to perform a mechanical operation that could be linear or rotary. Hydraulic actuators are composed of a cylinder used to pressurise liquid. This liquid pressure forces the diaphragm to move the valve actuator. Most hydraulic actuators use a piston to convert changing fluid pressure into mechanical power.

Advantages

They have high speed and can produce a large magnitude of force.

Disadvantages

Fluid leakage can cause various maintenance issues. It is expensive and requires additional equipment such as heat exchangers and noise controllers.

Pneumatic Actuators

Pneumatic actuators convert the energy of compressed air or gas into mechanical energy that regulates one or more components. They can produce linear or rotary movements depending on the machine’s design. The external compressive force stored within a compressive gas forces the piston inside a hollow cylinder to build pressure. This generates a force relative to the piston’s pressure that moves the load in a particular direction.

Advantages

They are durable, have a long operational life and require low maintenance. Air is a safer component to use and can work with very high temperatures.

Disadvantages

To reduce loss of pressure the air compressor must run continuously. Polluted air may require extra maintenance.

Electrical Actuators

Electric actuators are electro-mechanical devices capable of creating an action that requires a force like clamping by using an electric motor. The electric motor converts electrical energy into mechanical torque. They produce simple, safe and clean movements with accurate and smooth motion control. Electric actuators have a long life with a very low total operating cost.

Advantages

Produces less noise and is easy to use. They can be used to achieve high precision.

Disadvantages

It can only be used in places that satisfy certain environmental conditions. It is also expensive.

Thermal Actuators

These actuators are used in devices like thermostats, thermal bypass valves, thermostatic mixing valves and balancing valves and many more. Thermal actuators work on the basic principles of thermal expansion. They convert heat energy into mechanical movements. A typical thermal actuator consists of a temperature-sensing material sealed by a diaphragm that pushes against a movable piston. The temperature sensing material expands or contracts based on the device’s temperature, thus causing the piston to move.

Magnetic Actuators

Magnetic actuators use magnetic forces to produce motion. Most magnetic actuators work based on the Lorentz Force equation. Based on the components used to produce magnetic and repulsive forces, Magnetic actuators are of 3 types:

Moving Magnet Actuators, Moving Coil Actuators and Moving Iron Actuators.

Working of Actuators in IoT

A typical actuator is composed of the following.

- Power source: The energy input required to drive the actuator.

- Power converter: To supply power from the source to the actuator according to the measurements set by the controller.

- Actuator: The actuator device converts the energy it receives into mechanical force.

- Mechanical load: The mechanical system that is driven by the actuator.

- Controller: A controller ensures effective processing of system functions and is the control system of the actuator.

In simple words, an actuator converts energy into torque. This torque controls a mechanism or a system incorporated by the actuator. It helps in producing or preventing motion. The control system can be controlled by electrical or mechanical means manually or with the help of software. In DC motors, the rotor assembly rotates to align itself with the stator assembly. The stator assembly remains stationary. Work done by the rotor and stator assemblies is known as the primary and secondary windings within the motor. Voltage is applied to the primary assembly, thus inducing the flow of current to the rotor assembly, or the secondary winding. This interaction creates a magnetic field that produces motion.

Valves are the most common components that are controlled by actuators. The quality of a valve depends on many parameters such as metallurgy, mechanical resistance, machining, etc. The performance of a valve depends mainly on the actuator it uses.

Applications of Actuators in IoT

The actuators are ideal for installations where human interaction is impossible or dangerous. They are also used to greatly reduce manual work. They are used in material handling and cutting equipment that move up and down, valves that control the flow of raw materials, etc. Robotic arms in manufacturing industries also make use of linear actuator systems to achieve linear movement. They are also used to streamline processing, treatment, packaging, and other processes to ensure timely production and distribution. Home automation systems use actuators to control window and screen movements. Some other applications include agricultural machinery, solar panel movements, etc.

Check out this article - Components Of IOT

Frequently Asked Questions

What is the difference between an Electric Actuator and a Hydraulic Actuator?

Electric actuators use DC motors to drive a lead screw fitted with a nut that runs up and down. As the screw rotates, the nut is driven along those threads thus converting rotary motion into linear motion. Hydraulic actuators use fluid to push a ram to and fro. It consists of a piston that moves inside of a hollow cylinder due to liquid pressure.

What are the differences between sensors and actuators?

Actuators create movements, whereas sensors monitor environmental conditions such as fluid levels, temperatures or vibrations. Actuators measure heat or motion energy to determine the resulting action while sensors read the environmental conditions to perform a particular task. An actuator converts an electrical signal to physical action but a sensor converts a physical attribute into an electrical signal.

Conclusion

In this article, we have extensively discussed the role of Actuators in the Internet of Things. We started with a brief introduction to actuators and then moved on to explore the different types of actuators. We also discussed the working and applications of actuators.

Read more, What is arduino uno

Feeling curious? Check out Characteristics of IoT, Bluetooth with IoT and Cloud services for IoT to learn more. Explore our Library on Coding Ninjas Studio to upskill yourself in Data Structures and Algorithms, Machine Learning, Deep Learning, Cloud Computing and many more! Test your competency in coding by taking up our mock test series and participating in the contests hosted on Coding Ninjas Studio!

Upvote our blogs if you find them insightful and engaging! Happy Learning!